1. Shredder can be used for construction waste disposal

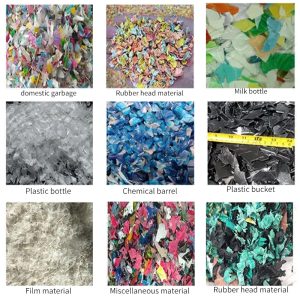

The construction process generates a lot of construction waste. These wastes usually include concrete, bricks, wood, metal, glass and plastic. Due to the complex composition of construction waste, it is very difficult to deal with it, but now there is a new treatment method, which is to use a shredder to shred the construction waste into small pieces and then reuse it.

Shredders play an important role in the disposal of waste resources in the construction industry.It utilizes the mechanics of shearing, tearing and crushing to effectively break large materials in construction waste, such as concrete blocks, bricks and tiles, wood and plastic, into smaller pieces. This process not only reduces the volume of waste, facilitates transportation and stockpiling, but also promotes subsequent sorting, recycling and resource utilization. For example, crushed concrete fragments can be made into recycled aggregates, while wood fragments can be used as a source of biomass energy.

Click here to view:https://www.dongdua.com/2024-large-double-shaft-shredder-machine/

2. The working principle of the shredder

When processing waste generated in construction, the crusher transforms large, complex construction waste into smaller pieces that can be easily transported, processed and reused through a series of efficient, organized steps.The following is the specific process of construction waste treatment by shredder:

Material Entry: The material enters into the shredding box through the feeding system, and the box carries the shredding blades.

Preliminary processing: the material through the shredding blade tearing, extrusion, shear and other integrated action, initially torn into small pieces of material.

Discharge: the shredded material is discharged from the screen mesh hole, and the material that does not meet the specifications continues to be crushed until the desired effect is achieved.

Shredders can be simply categorized by the different number of shafts. We can choose shredders with different numbers of shafts for different application scenarios. Construction waste can be subdivided into different shredders to achieve a better effect of recyclable resources.

The structure of single shaft shredder is single knife roller, the crushed particles are smaller and uniform. It can be used to shred paper, wood and brittle materials. The structure of double shaft shredder is double knife roll. The crushed particles are larger and uneven. It can be used to shred tires, metals and so on. The structure of four-shaft shredder is four knife rolls. The crushed particles are medium and more uniform. It can be used to shred polluted soft materials, tires and so on.

3. The important role of shredder in construction waste disposal

The “14th Five-Year” Circular Economy Development Plan proposes that the comprehensive utilization rate of construction and renovation waste should reach 60% by 2025 (50% by 2020), and that the demonstration project of resource utilization of construction and renovation waste should be carried out to build 50 demonstration cities for resource utilization of construction and renovation waste.

So in the past few years, governments around the world have also attached great importance to the treatment of construction and renovation waste, and often see construction and renovation waste projects around the world. Construction waste disposal after more than ten years of development, in fact, the process and mode has matured, while the construction waste because the composition is relatively simple, so the treatment process is not so complex.

Shredders play a very important role in the construction industry。It can well resource construction waste, in construction waste treatment, shredder also shows the characteristics of energy saving and environmental protection. Its crushing process is low noise and low energy consumption, which reduces the impact on the environment. At the same time, through the recycling of construction waste, it can also reduce the mining of new resources, reduce energy consumption and realize the recycling of resources.

In addition, the use of shredders in construction waste disposal also promotes the development of related technologies. With the continuous progress of shredder technology, its application in construction waste disposal is more and more extensive, and the processing efficiency and recovery rate are constantly improving.

4. Shredder in the construction waste treatment summary

It should be noted that when using the shredder to deal with waste generated in construction, it is also necessary to pay attention to safety and environmental protection issues. It should ensure that the operators are professionally trained and comply with the operating procedures; at the same time, it is necessary to do a good job in the maintenance and repair of the equipment to ensure the normal operation of the equipment.

In summary, shredder plays an important role in construction waste disposal. Through its efficient crushing capacity and wide range of applications, construction waste has been effectively treated and recycled, making positive contributions to environmental protection and resource recycling. In the future, with the continuous progress of technology and application deepening, shredder will play a greater role in the field of construction waste treatment.

Related articles:https://www.sohu.com/a/767174790_121091054

Post time: 7 月-03-2024