An essential shredder

2024Prefabricated houses sell well

The following images are all for conversion

An essential shredder

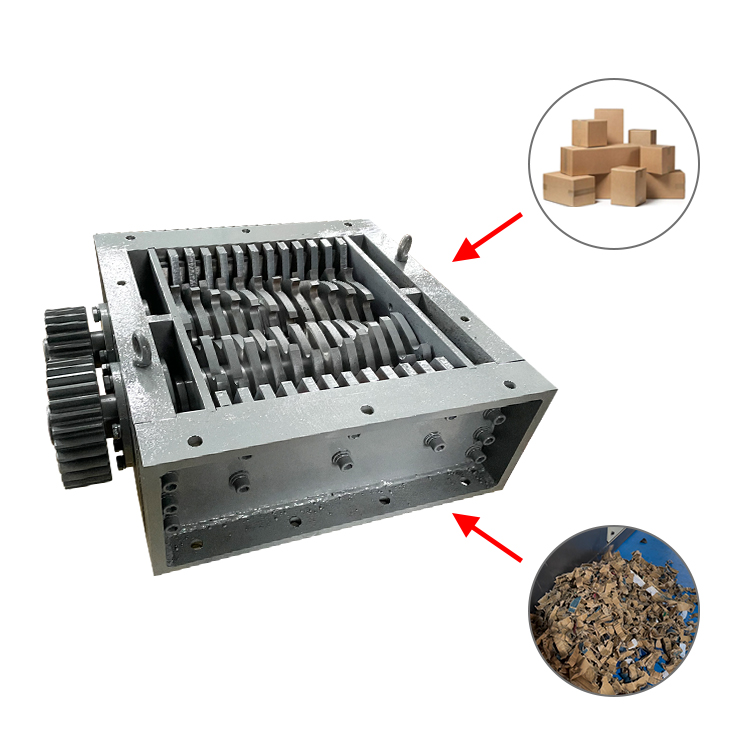

In the plastic industry, shredders are an essential equipment used to break large plastic materials into small pieces for subsequent recycling and reuse. With the increasing awareness of environmental protection, the demand for plastic shredders is also increasing. This article will provide a detailed introduction to the dual axis shredder, including its structure, working principle, application scenarios, advantages analysis, and successful cases, aiming to help readers understand this efficient and energy-saving plastic crushing solution.

The dual axis shredder is an advanced plastic crushing equipment, which is mainly composed of two main axes, each of which is equipped with several cutting tools. Through the dual axis rotational motion, the cutting tools cooperate with each other to crush the plastic material fed into the machine. The dual axis shredder has the advantages of simple structure, stable operation, and high crushing efficiency, and is widely used in various plastic crushing scenarios.

operational principle

The working principle of a dual axis shredder mainly relies on the rotational motion of the two main axes to crush plastic materials through the interaction between the cutting tools. After the plastic material is fed into the machine, it is gradually broken into small pieces by the cutting, impact, compression and other forces of the high-speed rotating tool. The broken plastic particles are filtered through a sieve to achieve the desired particle size distribution.

An essential shredder

An essential shredder

Application scenarios

The dual axis shredder is suitable for various types of plastic materials, including polyethylene (PE), polypropylene (PP), polyvinyl chloride (PVC), polyester (PET), etc. In the fields of plastic recycling and resource reuse, dual axis shredders play an important role. In addition, it is widely used in the recycling and processing fields of waste household appliances, automotive plastics, packaging waste, etc.

An essential shredder

Advantage analysis

Compared to other types of plastic crushing equipment, the dual axis shredder has the following advantages:

Efficient: The dual axis shredder can quickly break large pieces of plastic into small pieces, greatly improving the crushing efficiency.

Energy saving: The dual axis shredder adopts advanced mechanical structure, operates stably, and reduces energy consumption.

Wide application range: The dual axis shredder is suitable for various types of plastic materials and has a wide range of applications.

Environmental protection: By crushing waste plastics to reduce their volume, it helps to reduce the volume of waste and thus reduce its impact on the environment.

An essential shredder

Case sharing

A certain waste plastic recycling and processing enterprise used a dual axis shredder to successfully crush a large amount of waste plastic into small pieces, which were then classified, cleaned, melted, and processed to produce high-quality recycled plastic particles. The enterprise has not only improved recycling efficiency but also reduced production costs by using a dual axis shredder, achieving dual economic and environmental benefits.

Future outlook

With the continuous improvement of environmental awareness and the continuous development of plastic recycling technology, the application prospects of dual axis shredders will be even broader. In the future, the dual axis shredder will be further developed and improved in the following areas:

Energy efficiency improvement: With the continuous improvement of energy awareness, improving the energy efficiency of dual axis shredders will become an important research direction. By improving the mechanical structure and optimizing the control system, the energy efficiency of the dual axis shredder can be improved and energy consumption can be reduced.

An essential shredder

Intelligence: With the continuous development of artificial intelligence technology, future dual axis shredders may achieve intelligent control. By introducing technologies such as sensors and intelligent algorithms, the self diagnosis and automatic adjustment functions of the equipment can be achieved, improving the operational stability and production efficiency of the equipment.

An essential shredder

Diversified applications: With the continuous emergence of various new plastic materials, the application range of dual axis shredders will be further expanded. For example, in the automotive manufacturing industry, a dual axis shredder can be used to crush automotive plastic parts and produce high-quality recycled plastic particles for manufacturing new automotive parts.

Post time: 4 月-15-2024