2024Universal shredding equipment

The advantages and characteristics of plastic shredders are: sufficient power, high tearing force, wide applicability, and strong controllability. Almost all kinds of daily necessities we encounter in our lives, such as plastic films, wood, color steel tiles, cans, and paint buckets, can be shredded using plastic shredders. Plastic shredders generally use dual electric motors and dual reducers to provide uninterrupted power sources for crushing work. The electric motor, reducer, and cutterhead are collectively referred to as the core components of the shredder. We can choose a reasonable configuration plan based on the properties of the crushed material.

2024Universal shredding equipment

Plastic shredder is a versatile shredding equipment that brings new hope to our daily life and drives development. There are many manufacturers of plastic shredders now, and the models and configurations of plastic shredders are different. When choosing a plastic shredder, you need to choose the appropriate configuration based on your own material type and output, and it can also be customized. Choosing a good brand can bring high profits and high output to your future work.

The width of the discharge port of the metal shredder can be adjusted according to the user's needs at any time. By adjusting the position of the bracket (using two pairs of bolt screws on the side of the machine), the gasket can be placed behind the bracket, and then the bolt screws can be loosened to obtain the required discharge port size. The upper part of the machine is equipped with a feeding hopper, and a feeding adjustment baffle is set in the middle. This baffle can be adjusted towards the main and negative shredding chamber sides. Its function is to control the feeding amount in the two shredding chambers by the tilt angle of this board. The design of this machine adopts a single and double ear movable jaw embedded structure, which is completely different from traditional shredders in terms of structure.

2024Universal shredding equipment

The setting of the reset spring is limited by its structure and can only be done in the current way, which is to pre tighten it in the form of a tension spring in the middle of the rear of the two moving jaws. So using metal shredder equipment to process steelmaking and ironmaking is a very effective way, and the low cost is relatively popular. Working principle of metal shredder equipment: The main structure of the metal shredder is composed of a hopper, a frame, a fixed jaw, a moving jaw, a transmission part, a motor, and other components. The working principle is that the motor drives the belt pulley, balance wheel, spindle (eccentric shaft), and moving jaw. In the relative motion between the fixed jaw and the moving jaw, the material is torn multiple times with small eccentricity and high swing frequency to achieve the requirements of tearing (fine crushing).

Due to the limitations of the machine's performance (negative support, zero suspension) and mechanical structure, a single and double ear movable jaw inlay structure was adopted in the design, making the machine's structure very compact. A metal shredder is a machine used for the rough crushing of large volume materials, including waste cars, bicycles, aluminum scraps, and other materials. The shredded materials are in the form of strips or blocks, and can be recycled and reused through metal crushers or direct metal sorting.

2024Universal shredding equipment

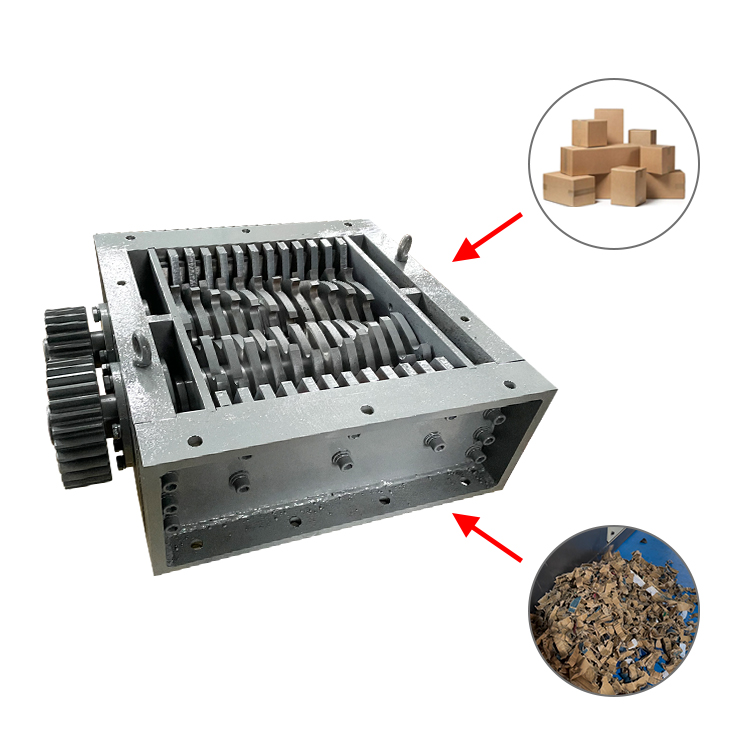

The cavity of the metal shredder adopts an inward concave pressure knife roller group structure, including two main spindle knife rollers. The knife rollers are equipped with a hexagonal structure knife disc, and the shredding fixed knife is welded on the shredding cavity. The fixed knife and the moving knife on the knife roller bite each other during equipment operation, completing the shredding treatment of metal materials based on the principle of shearing. At the same time, in order to ensure that the material is not squeezed out, the cutter head of the shredder adopts a claw structure, and the number of claws is determined based on the volume shape of the shredded material and the discharge size of the shredded material. The higher the material hardness, the more claws there are, and the smaller the shredded fragments obtained after shredding. Similarly, the opposite is true: the larger the shredded fragments, the smaller the hardness of the shredded material. At the same time, the concave structure of the metal shredder's shredding chamber ensures that the shredded material will not be squeezed out. After the material enters the shredding chamber, it automatically squeezes from both ends to the middle gap, which can reduce the material loss rate, improve the shredding effect, and increase work efficiency.

1. No abnormal noise

A good metal shredder will not make any abnormal noise during operation, which is also a standard for judging its performance and quality.

2. Blade hardness

Due to the fact that metal shredders mainly handle metal waste, it is necessary to meet the hardness standards of the blade, which is sufficient to make it more wear-resistant during the cutting process.

3. Box quality

Good quality of the casing is the guarantee for the stability of the metal shredder during operation. If steel plates are used to be sturdy and durable, it will ensure that the metal waste does not cause too much impact during the extrusion and cutting process.

Post time: 4 月-15-2024