2024High quality plastic shredder

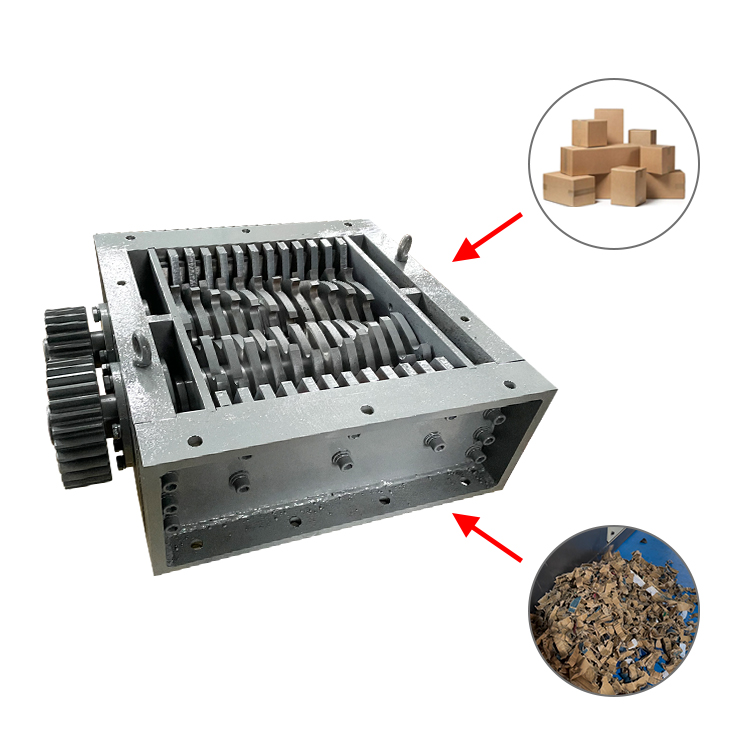

Advantages of a dual axis shredder:

1. The dual axis shredder uses heavy moving blades with high crushing efficiency, and its cutting tools are made of alloy steel casting, which is sturdy and has a long service life.

2. The frame board is thick and can withstand high torque, making it sturdy and durable.

3. Adopting microcomputer (PLC) automatic control, it has various functions for starting, stopping, reversing, and overload automatic reversing control.

4. It has the characteristics of low speed, high torque, low noise, and low dust.

5. Easy to adjust, low maintenance cost, economical and durable.

6. The thickness of the cutting tool and the number of claws can be changed according to different materials.

2024High quality plastic shredder

Instructions for use and maintenance of shredder:

1. Before starting the test drive, it is necessary to strictly check whether the installation of various parts of the machine meets the requirements, whether the screws and bolts are loose, and gently pull the belt by hand to try running, whether there is any collision with the shell or other phenomena. At the same time, check the direction of rotation and strictly prohibit crushing flammable and explosive materials to avoid accidents.

2. During production, uniform feeding should be maintained to ensure the quality of crushing and normal production. At the same time, overloading of the motor is strictly prohibited to ensure the normal operation of the machine.

3. In addition to regularly checking for loose fasteners in various parts, attention should also be paid to checking the wear of vulnerable parts. If the wear is severe, it should be replaced in a timely manner to avoid damaging the main components, and necessary fire prevention measures should be taken.

4. Due to the high rotational speed, in addition to being installed correctly and firmly, good lubrication should also be maintained to maintain the normal operation of the machine. Under normal circumstances, it is normal for the bearing temperature to not exceed 70 degrees. Add butter and molybdenum disulfide to the host bearings once a week, and high-speed butter has a better effect.

2024High quality plastic shredder

The plastic shredder consists of a shredding mechanism, a bracket, a recycling box, and a cart. The size of the equipment is determined by the size of the material and the amount of material processed. The plastic shredder is designed with a filter screen device inside. When the plastic shredder is working normally, the filter screen plays a role in separating materials and liquids, effectively recycling and reusing the liquid remaining on the bottle,

Features of Multi functional Plastic Crusher: This machine is suitable for crushing and recycling soft plastics. The scissor shaped knife frame structure specially designed for the crushing of thin film materials is conducive to improving work efficiency. The plastic film is directly fed into the crusher, and through the motor transmission reducer transmission spindle, N moving knives installed on the spindle and fixed knives installed on the frame are used to tear the entire bundle of plastic film. The plastic film is separated from debris (such as stones) through a separation water tank to obtain recyclable raw materials.

The plastic film shredder adopts a dual axis independent drive, which generates corresponding pressure on the material during production, achieving automatic feeding function. The unique blade shaft structure and four corner rotating cutting tools will not cause entanglement or jamming of the equipment during low-speed and high torque production, thereby improving production efficiency. This equipment is used for various toughness and high viscosity material crushers.

2024High quality plastic shredder

classification

If plastic shredders are classified according to the object of tearing, they can be divided into various categories: hard plastic shredders, strong plastic shredders, and plastic pipe shredders.

The metal shredder is mainly composed of a shredder blade group, a load-bearing box, a box bracket, a feeding system, a power system, and an electrical control system. It is mainly used to cut and squeeze large metal materials or large diameter circular pipes that are inconvenient to transport through the metal shredder, and tear them into sheet materials that meet customer requirements. It is suitable for metal shredding in various industries at present.

Working principle of metal shredder:

Large metal materials enter the shredder knife box through the feeding system, and the materials pass through

The shredder blade shaft rotates in both directions, and the adjacent cutting edge of the moving blade on the blade shaft forms a shear. The moving blade tip and the cylindrical surface of the spacer sleeve form a shear, and the torque and speed difference of the blade shaft form a tear. This causes the material to be compressed and torn into small pieces during production, which are discharged from the lower part of the box.

Advantages of metal shredders:

1. After shredding, the transportation of materials is convenient, which can effectively reduce transportation costs and increase transportation efficiency;

2. The shredded material is easy to crush for secondary processing;

3. Shredded materials are easier to store compared to large pieces of metal, which can save a lot of warehouse space;

4. The processed and broken pieces are uniform and have low loss. Multiple screens can be replaced simultaneously to meet different needs;

5. The body is welded with high-strength steel plates, which can withstand high torque and is sturdy and durable;

6. High power motors and reducers ensure high torque, high output, and no jamming or other issues;

7. Equipped with larger pulleys to increase the inertia of the shredder, it can save energy and provide strong shredding;

8. According to different customers tearing different products, special shredder blade shapes are designed. The shredder blade is made of alloy tool steel of different materials, which can tear high-strength automotive panels with a strength of 800-1000Mpa, making the blade durable, high-yield, and uniform discharge particle size.

9. Low noise and less dust;

10. Adopting microcomputer (PC) automatic control, equipped with start, stop, reverse and overload automatic reverse control functions.

Post time: 4 月-15-2024