2024 Large plastic shredder

A shredder is a machine that breaks large pieces of waste plastic into small pieces through a high-speed rotating disc, making it easy to transport and recycle. In the production process, we can crush large pieces of plastic into small pieces, which is not only beneficial for recycling after crushing, but also can save costs. When the shredder is working, the blade rotation speed is very fast, which can crush plastic and other metal materials into small particles.

2024 Large plastic shredder

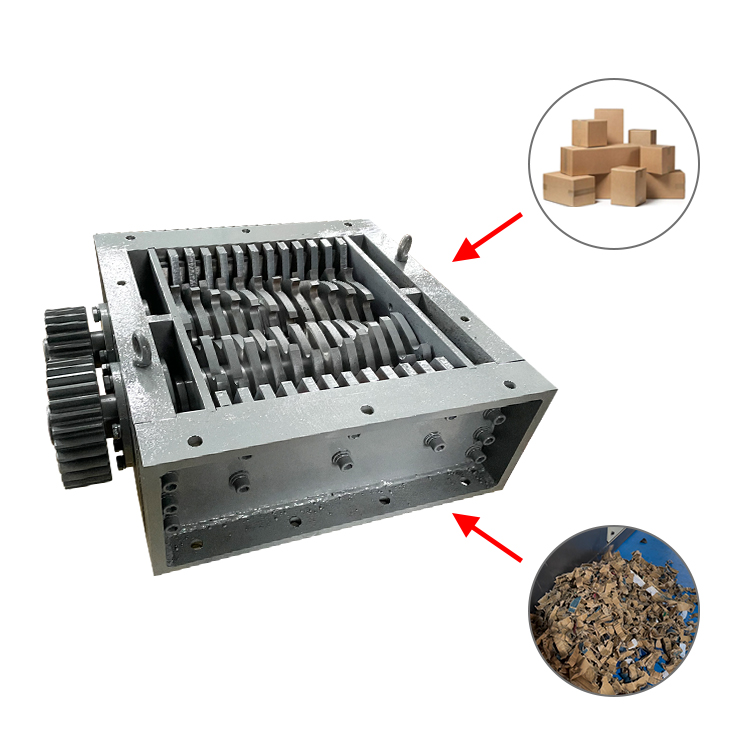

The shredder mainly consists of components such as a frame, motor, cutterhead, cutter shaft, bearing seat, main shaft, and tail cover. The main function of a shredder is to shred various irregularly shaped waste plastics.

The function of the blade shaft is to rotate the motor shaft, drive the blades on the main shaft to rotate, and flip the material plate through the blades. There are many holes on the cutter shaft that can be connected to screws on the motor shaft or spindle. When the spindle rotates, these holes will open, allowing the material to pass through and crush it. If the cutter shaft size of the shredder is too large, it will affect its normal operation.

2024 Large plastic shredder

1. The blade is the core component of a shredder, which can directly crush waste plastics. Therefore, the quality of the blade has a significant impact on the performance and service life of the entire machine.

2. The blades of plastic shredders are generally cast from alloy steel, which has high strength, good wear resistance, and strong corrosion resistance. In the blade manufacturing process, advanced welding technology is used to ensure the normal operation and service life of the equipment.

3. The blades of the plastic shredder can also be replaced, and different specifications of waste plastics can be replaced according to actual needs.

2024 Large plastic shredder

The bearing seat is composed of a central shaft, bearings, and some adjustment bolts. The central shaft connects the left and right bearings together, and the axial position of the bearings is changed by adjusting the bolts, thereby changing the axial and radial forces to control the amount of material in the crushing chamber.

The shredder blades are made of special wear-resistant materials, which can ensure that they will not wear during operation and have high wear resistance and corrosion resistance. The blades of the shredder are installed on the disc and crush waste plastic through high-speed rotation of the blades. When the electric motor starts, the cutterhead will start to rotate, and then the motor provides power to rotate the blades on the cutterhead at high speed to crush waste plastic.

The spindle is the driving force for the rotation of the cutterhead, and its function is to drive the operation of the entire shredder through the spindle. In order to meet the production needs of users, we choose high-quality bearings, high-quality spindles, and high-strength steel.

The shredder is suitable for shredding materials such as plastic, paper, wood, and waste electrical appliances. Due to its small size, light weight, convenient operation, simple operation, and easy maintenance, users should pay attention to maintenance and upkeep when using the device to ensure its normal operation. When the shredder is working, attention should be paid to:

When raw materials enter the machine, no iron or metal objects are allowed to enter the machine.

2. Do not handle hard materials during machine operation to avoid damaging the machine.

When abnormal sounds or phenomena are found, the equipment should be immediately stopped and stopped for inspection.

Tail cover

1. The blade is a high alloy wear-resistant blade, suitable for crushing various materials and has high shear capacity.

2. Plastics of different materials can be torn apart, and other metals can also be torn apart.

3. The structure design of the cutter shaft, bearing seat, and tail cover is reasonable and has strong overload resistance.

The number of knife groups can be adjusted according to actual needs to meet the crushing requirements of different materials.

5. The driving device is driven by a constant speed motor, which runs smoothly and has low noise.

6. It has overload protection function and stepless speed regulation function, with simple operation and convenient use.

7. The shredder is made of all stainless steel, which is sturdy and durable.

8. The whole machine is a fixed structure, with a small footprint and convenient movement.

9. Silencers and vibration damping devices are installed on the machine to ensure smoothness and noise during operation.

Post time: 4 月-15-2024